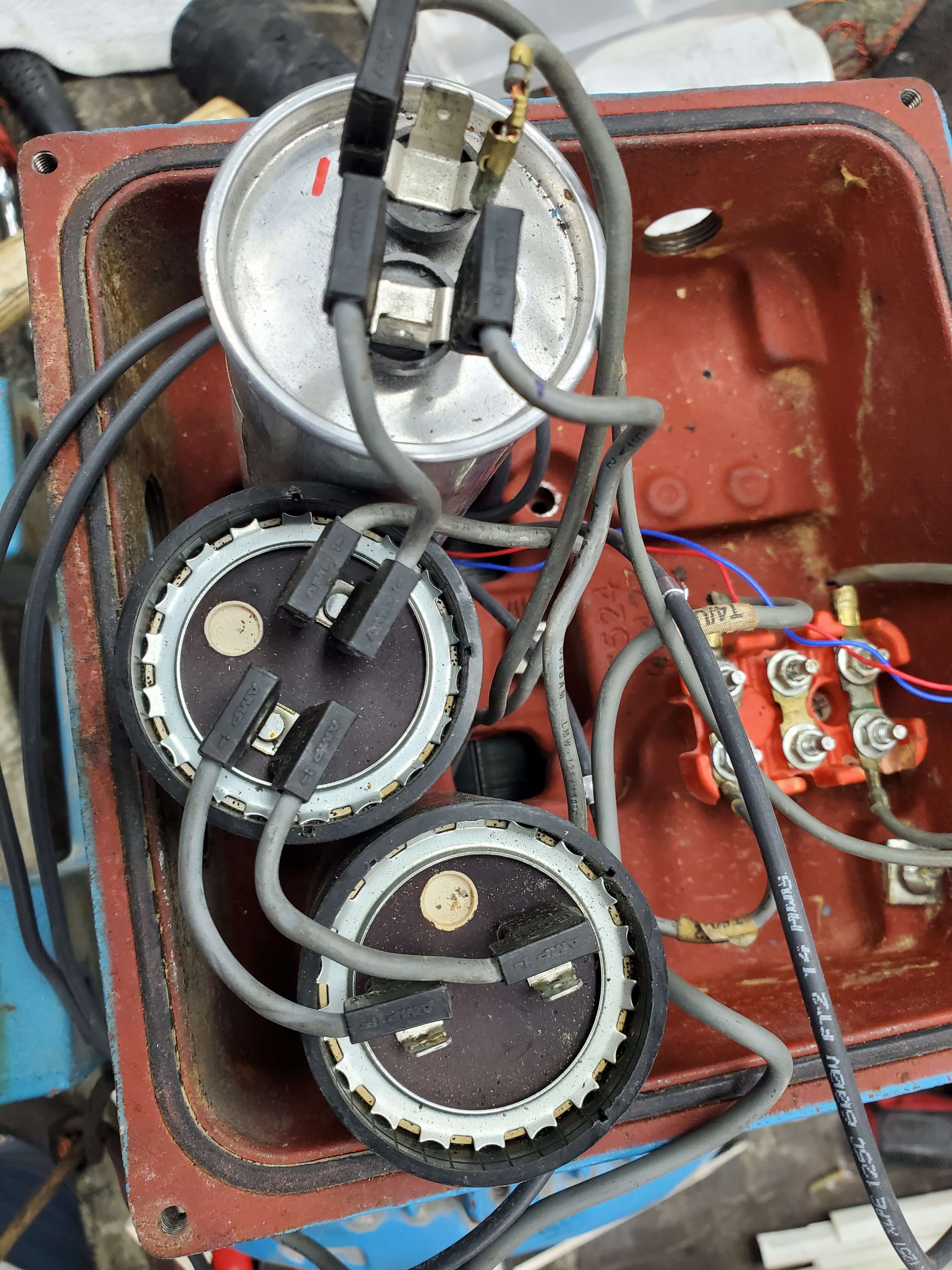

AC/DC

Drive

Repair

Visual inspection and signature analysis to test components.Common failure parts (capacitors, transistors, power supplies) are checked and replaced.Waveform analysis and dummy load testing ensure output integrity. Full load testing with a dynamometer confirms performance.The unit is cleaned, retested, and shipped. Chart

Recorder

Repair

Disassembly and power component testing for damage or loose connections.Component-level troubleshooting and repairs for optimal functionality.Factory default settings and signal verification to match manufacturer specs.Final cleaning and retesting for quality assurance.Circuit

Breaker

Repair

Contact closures and trip timing are tested with high current.Magnetic trip adjustments and shunt trip tests ensure accuracy.Faulty contacts and trip mechanisms are replaced.Full cleaning and retesting before shipment.CNC

Controls

Repair

Visual inspection of connectors, PCBs, and operator controls.Common failure components are tested and replaced.Voltage supply and I/O functions verified per OEM specifications.Final testing ensures system reliability.Counters

&

Timers

Repair

Mechanical and electrical timers checked for accuracy.Relays, oscillators, and logic functions tested and replaced as needed.Signal generators verify proper count and timing functionality.Complete cleaning and retesting before dispatch.Encoder

Repair

Visual and rotational stress tests performed on the gratical and shaft.Signals verified to match OEM pulse/count specifications.Defective components identified and replaced.Final testing and thorough cleaning before shipment.Flow

Meter

Repair

Sensor wheels, mechanical parts, and circuits are tested for damage.Simulated flow testing verifies proper output and set points.Transmitter signals tested for accuracy and adjustments made..Unit is fully cleaned and retested before final shipment.I/O

Modules

Repair

OEM-specific test stations identify faults.Power supplies, drivers, and transistors are inspected and replaced.Ladder logic and current loads verified.Final cleaning and performance verification.Industrial

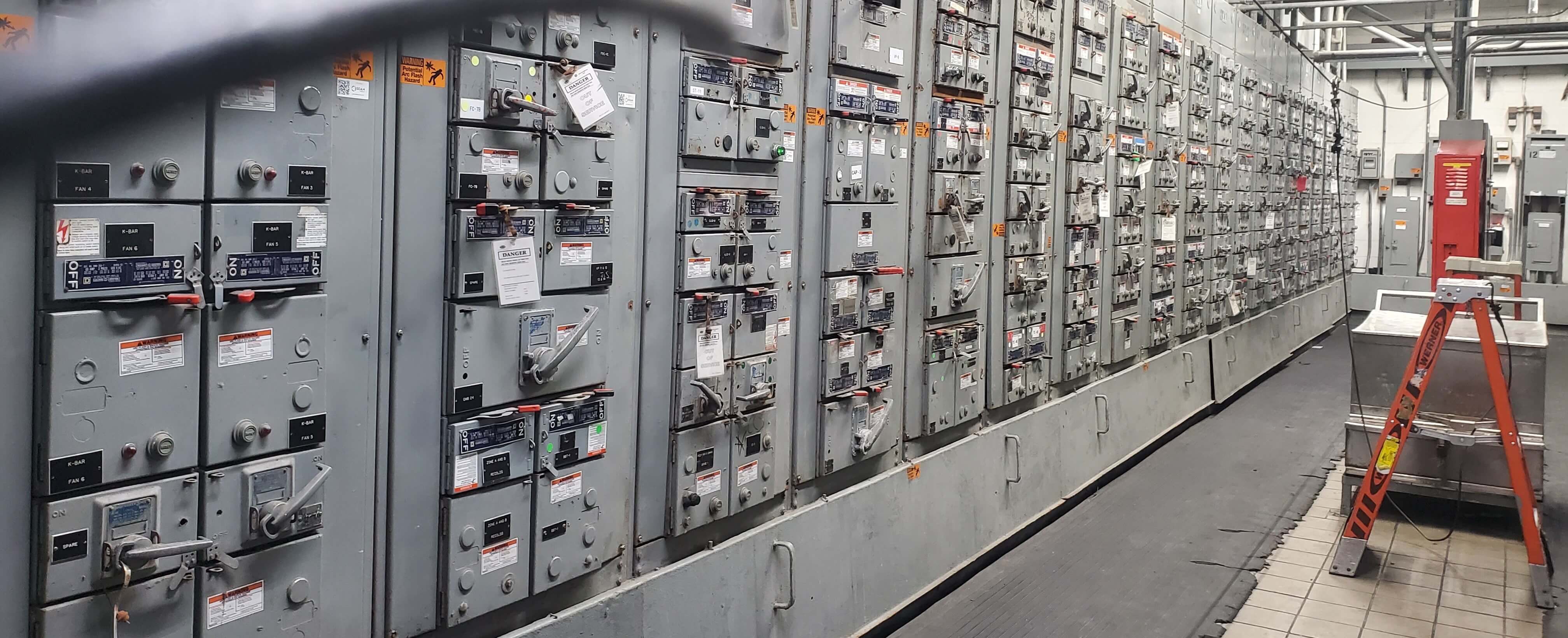

Controls

Repair

Power components and output relays inspected and replaced.Internal power supplies verified for proper voltage output. Software and control functions tested with a small program.Final cleaning and retesting before delivery. Industrial

Monitors

Repair

CRT-Based:

Power supply and horizontal circuits tested for shorts. Flyback and video alignment checked with an OEM monitor analyzer. Capacitors and high-failure components replaced. Final cleaning and retesting before delivery. LCD-Based:

Backlights, inverters, and capacitors tested and replaced. White balance and color temperature verified.Final testing ensures OEM compliance. PLC

Repair

Power applied to verify input/output functionality. Capacitors, relays, and isolators replaced as needed. Ladder logic and battery backup tested. Final unit cleaned and retested. Power

Supplies

Repair

Input circuits inspected for shorts or faulty components. Output voltage and regulation tested under full load. Sense circuits checked for proper operation. OEM compliance verified before shipping. Printed

Circuit

Boards

Repair

Visual inspection for missing or damaged components. All circuits tested using precision diagnostic tools. Defective components replaced, and full functionality verified. Final cleaning, recoating, and anti-static packaging. Robotics

Repair

Surface inspection and mechanical component testing. Electromechanical assemblies fully diagnosed and repaired. Front panels, power supplies, and cables inspected. Final system power-up, cycling, and load testing. Safety

Equipment

Repair

Light

Curtains

&

Scanners:

Lenses and connectors inspected for damage. Motor and scanning communication verified. Alignment and output signals tested for accuracy. Servo

Drives

Repair

Power components, feedback circuits, and MOSFETs inspected. Universal tester verifies phase, rotation, and load performance. Final full-load test ensures precision operation. Soft

Starts

Repair

SCRs, gates, and power supplies tested before applying power. 3-phase power and control voltage checked for performance.Full-load testing ensures correct timing and bypass operation. Spindle

Drives

Repair

Surface defects and shorted components tested. Common failure parts replaced for smooth operation. Dynamometer testing eliminates ripple and velocity errors. Repair

Turnaround

&

Emergency

Service

At Industrial EQ Diagnostics, we work efficiently to minimize downtime and restore operations quickly.

Need

Emergency

Repair?

On-call technicians are available 24/7, 365 days a year. Troubleshooting support. Fast rush repair service. Access to our vast inventory of surplus equipment.When downtime is not an option, trust Industrial EQ Diagnostics to provide fast, expert repair solutions tailored to your needs.