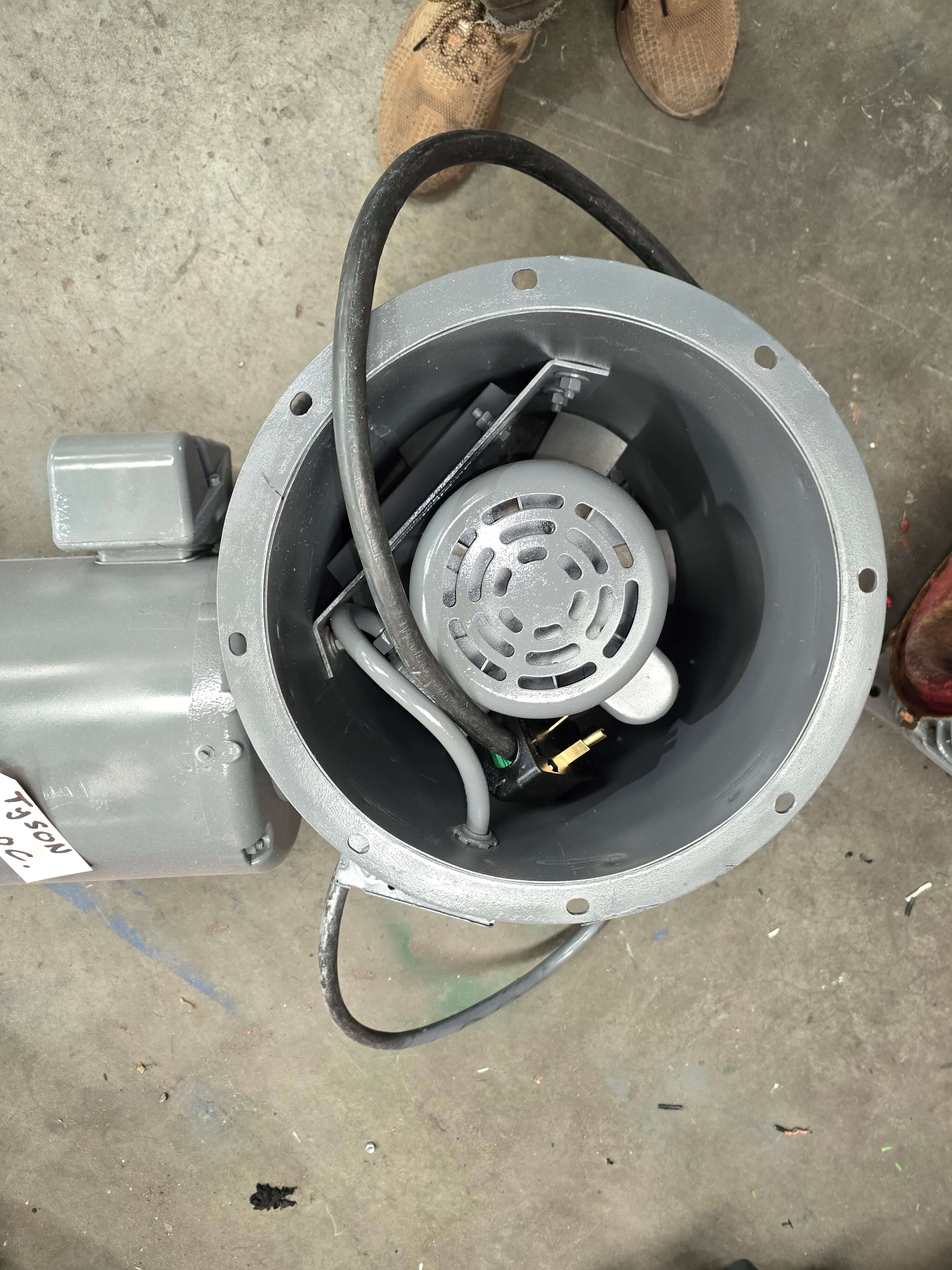

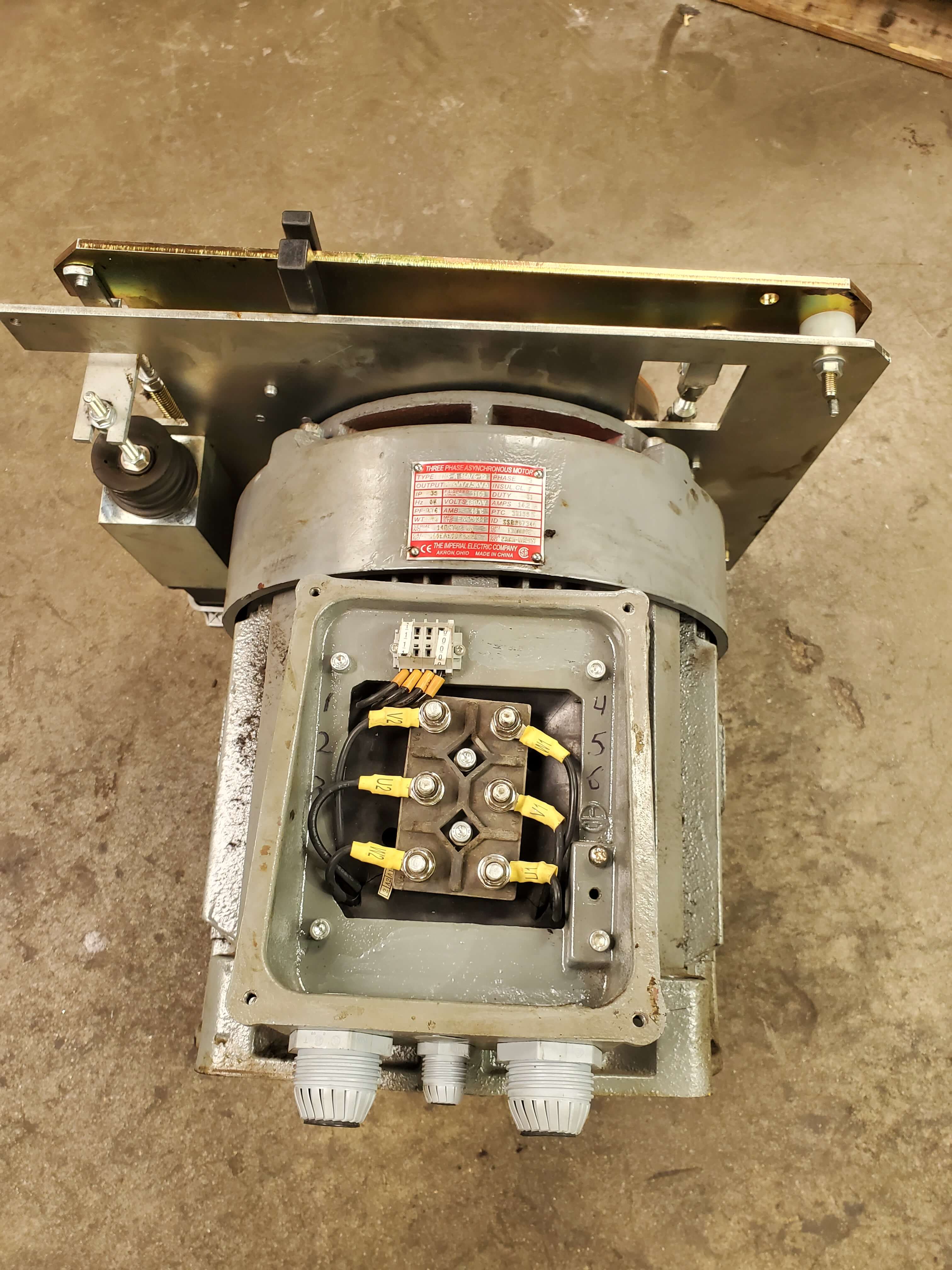

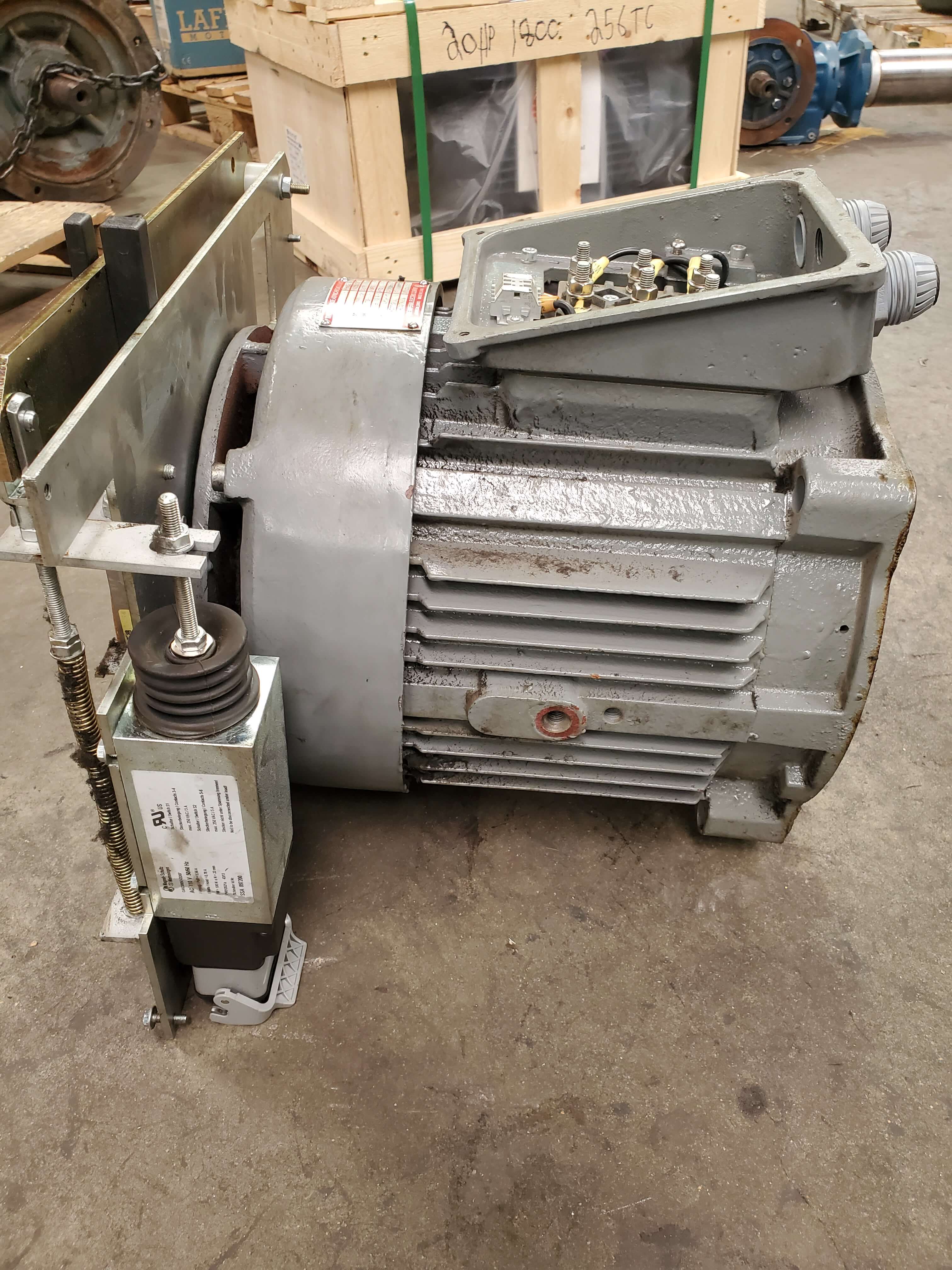

At Industrial EQ Diagnostics, we provide complete machine shop and motor rewinding services for electric motors of all shapes and sizes. As an industry-leading partner, we’re focused on getting your motor back up and running so your operations can reduce downtime and restore profitability.

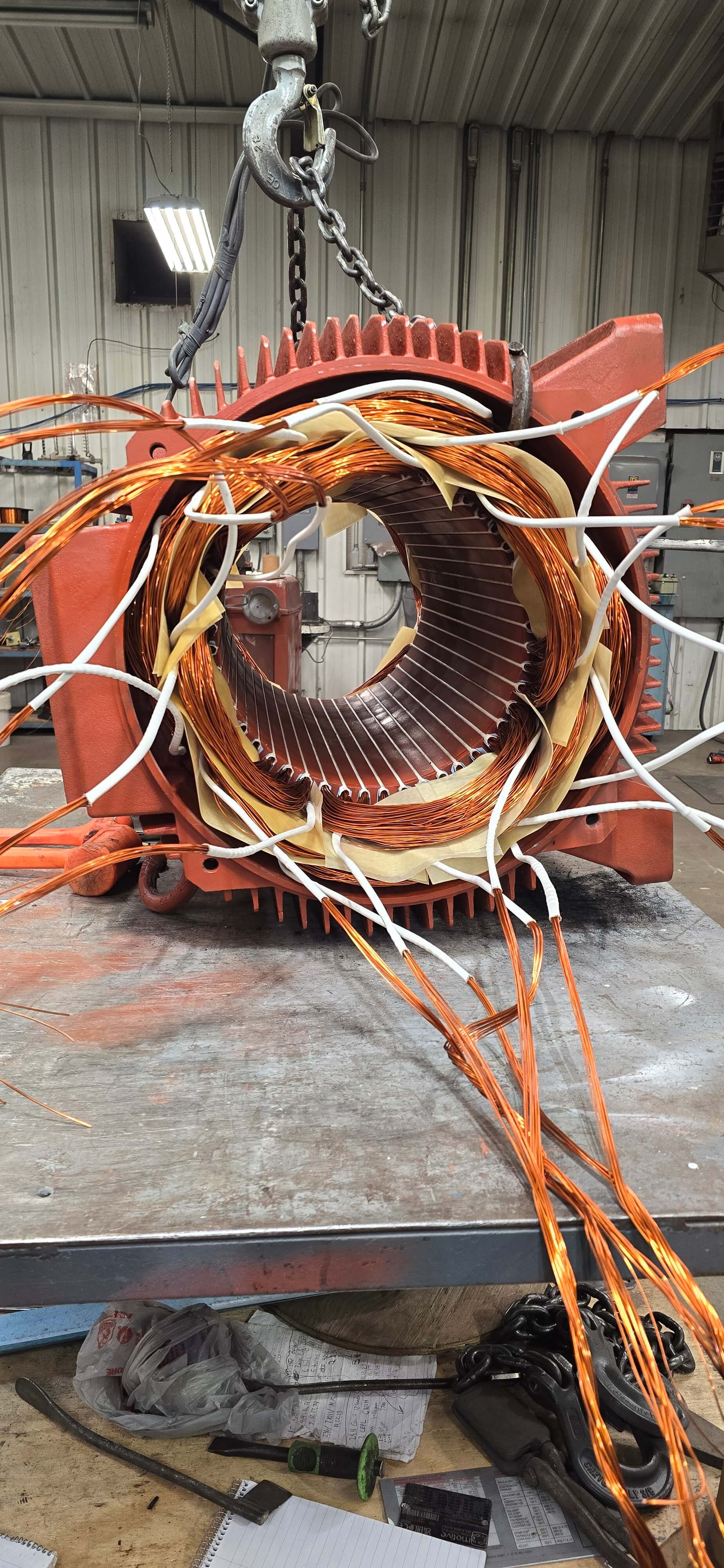

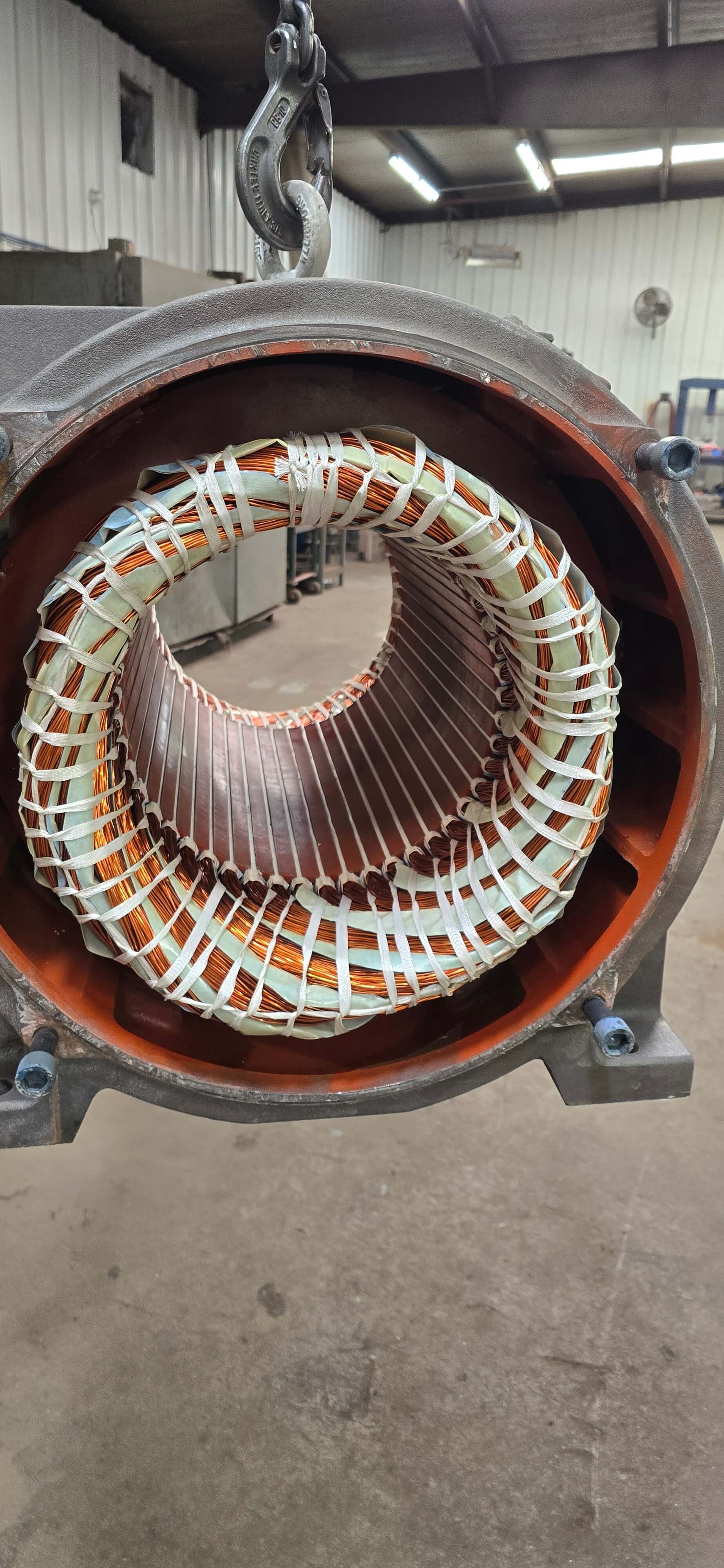

Why do you need Electric motor rewinding and Electric motor rebuilding services? Sometimes we will repair shorted, grounded, or damaged motor coils by rewinding them. You can provide us with your motor and when we are able to complete our DC motor rewinding service on your motor, we can return the rewound coil and reinstall it with a rebuilt armature or others so that your motor will run back the way it should.

Even the most durable motors are susceptible to degradation over time. Here are signs that it might be time to rewind an electric motor:

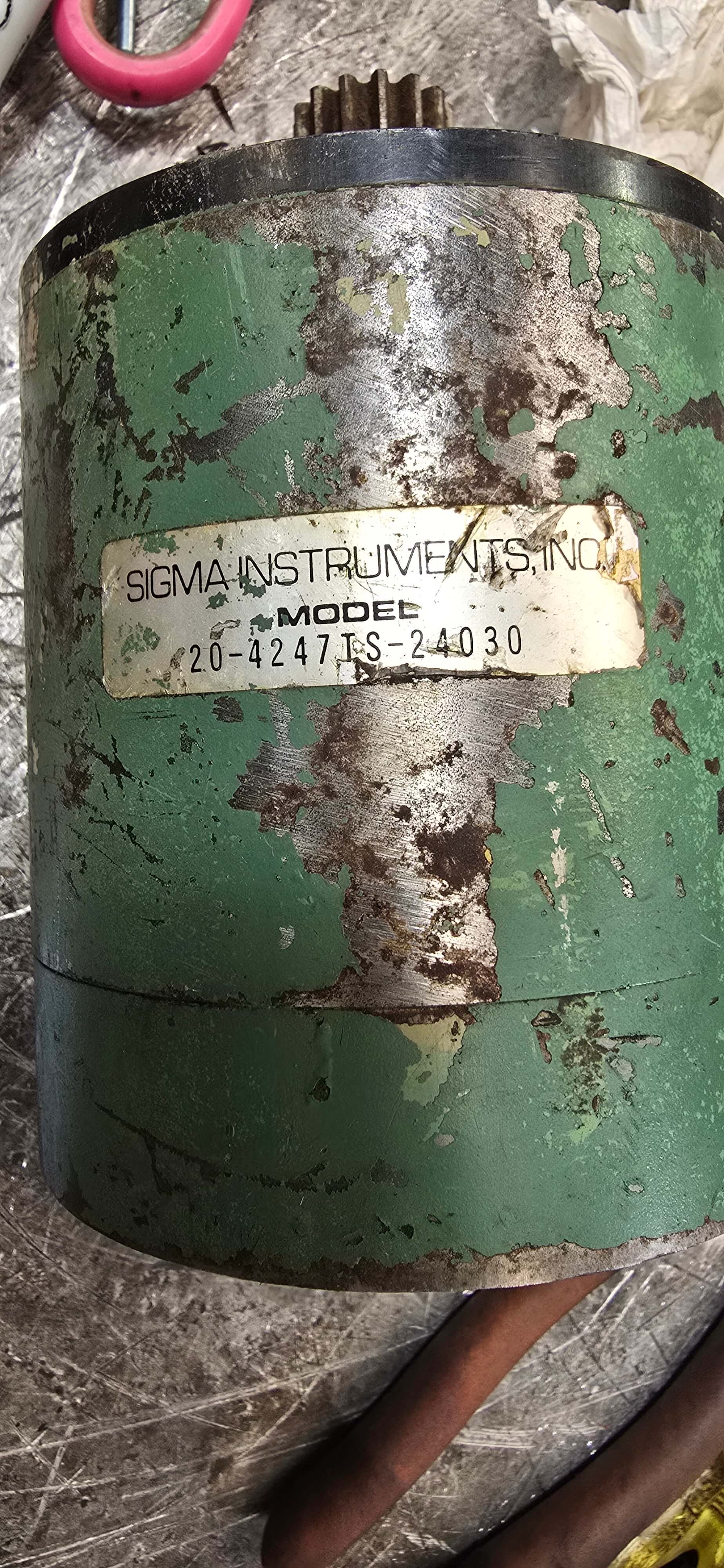

It is one of the tell-tale signs that a motor needs to be rewound. Your company may see broken elements, burns, or contamination like rust or moisture.

If you observe signs of degradation, your company will want to determine if your motor’s laminations follow suit. If so, you may need to get a new motor. If this is not the case, fast-forwarding may be the right way to go.

Your company may notice a poor winding resistance on a motor or a professional may measure it. An example would be a technician using the winding resistance test to verify whether defective coils in the motor are affecting performance.

To start assessing winding resistance, locate the motor’s nameplate or consult the motor’s manufacturer instructions that accompany the motor. One of these locations is going to indicate the motor's optimal winding resistance level. If the measured numbers are far from optimum, you probably need to rewind.

A motor in need of rewinding may sometimes exhibit motor issues related to insulation resistance, as the coils in the actual motor begin to short.

There are many reasons why, such as high-power surges, high vibration, and contamination that can cause shorting and low insulation resistance. A motor that requires rewinding can cause these problems. Low insulation resistance creates many problems, including lack of lubrication and damage to the engine components.

In certain situations, motor replacement can be a more worthwhile option than motor rewinding. On one hand, doing so is far more costly than replacing the motor. As well as saving you money in the immediate term, rewiring means that you get to make the most of your current motor for that bit longer. On the other hand, the extra investment may be worth it, as it nets you a new engine with years of top performance.

Rewinding is usually cheaper and greener as they reuse the core motor materials. Starting fresh with all-new materials to create a new motor comes with a vastly greater carbon footprint and general environmental hit.

But this rule of thumb becomes more complex when you factor in the fact that a new motor might offer cost savings and environmental savings through greater energy efficiency. So your company might need to crunch some numbers to decide the best solution for your operations and budget.

How do you differentiate between the two situations? If a motor is quite old, in general, a replacement may be of better value than REWINDING, as it will break down or need ARK REWINDING more often. Or an aging motor might be so badly damaged that rewinding it would not return it to useful service. But if the motor is relatively new, rewinding is a low-cost option for improving performance and prolonging a generator's useable life.

Your company will likely want to rewind a motor if most of these conditions apply:

On the other hand, your company may need to replace the motor if most of these conditions apply:

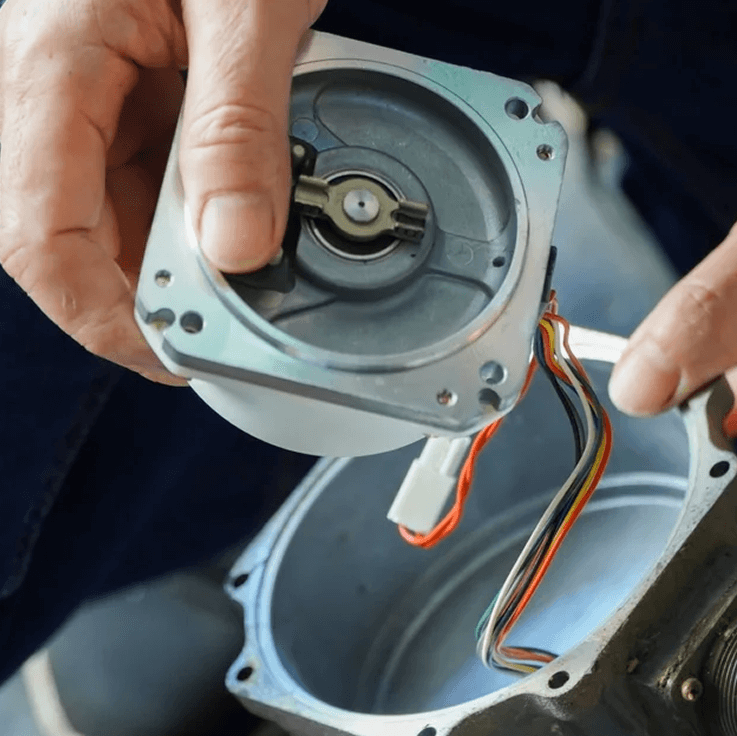

There are many steps to electric motor rewinding services we follow when providing services:

This may sound like an extremely involved process, but for our trained repair technicians at Industrial EQ Diagnostics, it is practically automatic. Our technicians have wound literally hundreds of thousands of motors and it has become second nature. When you call Industrial EQ Diagnostics for your motor rewind and repair services, you can rest assured that you will end up with a quality motor that works almost brand new when it is all said and done.

Here are some of our primary machine shop services:

Industrial EQ Diagnostics has been perfecting the process of rewinding AC and DC motors for exceptional repair and rebuilding.

A well-designed and properly performed motor rewind will have no efficiency degradation on electric motors, but you will see increases in power density, reliability, and overall efficiency as a result of the cutting-edge equipment and practices employed by your Industrial EQ Diagnostics certified technician.

Perhaps some other upgrades have crossed your mind during your rebuild and motor rewind, like the latest resins and insulating tapes, which will improve overall thermal dissipation, particularly if you are working with an older machine.

As a qualified service provider, we guarantee the rewound motor is returned to OEM standards and efficiency expectations. So the complete analysis is first towards a fantastic rewinding service for electric motors, to step back and check if the motor has got any fault that the in submitting process he or she did not realize.

If we find something, we’ll immediately reach out to you with an updated quote and details of our concern. We need your approval for each and every work in order to ensure both parties agree on the final amount.

Motor rewinding is highly standardized but we follow very strict guidelines to ensure speed and fast service without interference to core integrity. Here are the key components of our process:

Industrial EQ Diagnostics is your reliable source when your company is searching for electric motor rewinding near you. With our top-tier machine shop and electric motor rewinding services, your company can stop worrying about your motor the moment you send it to Industrial EQ Diagnostics. We have the right technicians available, equipment, parts, and machining capabilities to get your motor up and running at peak efficiency.

To give you peace of mind, all of the motor repair work we carry out is covered by our 2-year In-Service Warranty. That’s why we offer an industry-leading 12-month warranty on all our electric motor rewinding services.We provide your company the security it needs with a great partner that's available 24/7/365 to support you. We’ll have you back on your feet as soon as we can, so call us for a quote and inquire about our one- to two-day rush service.