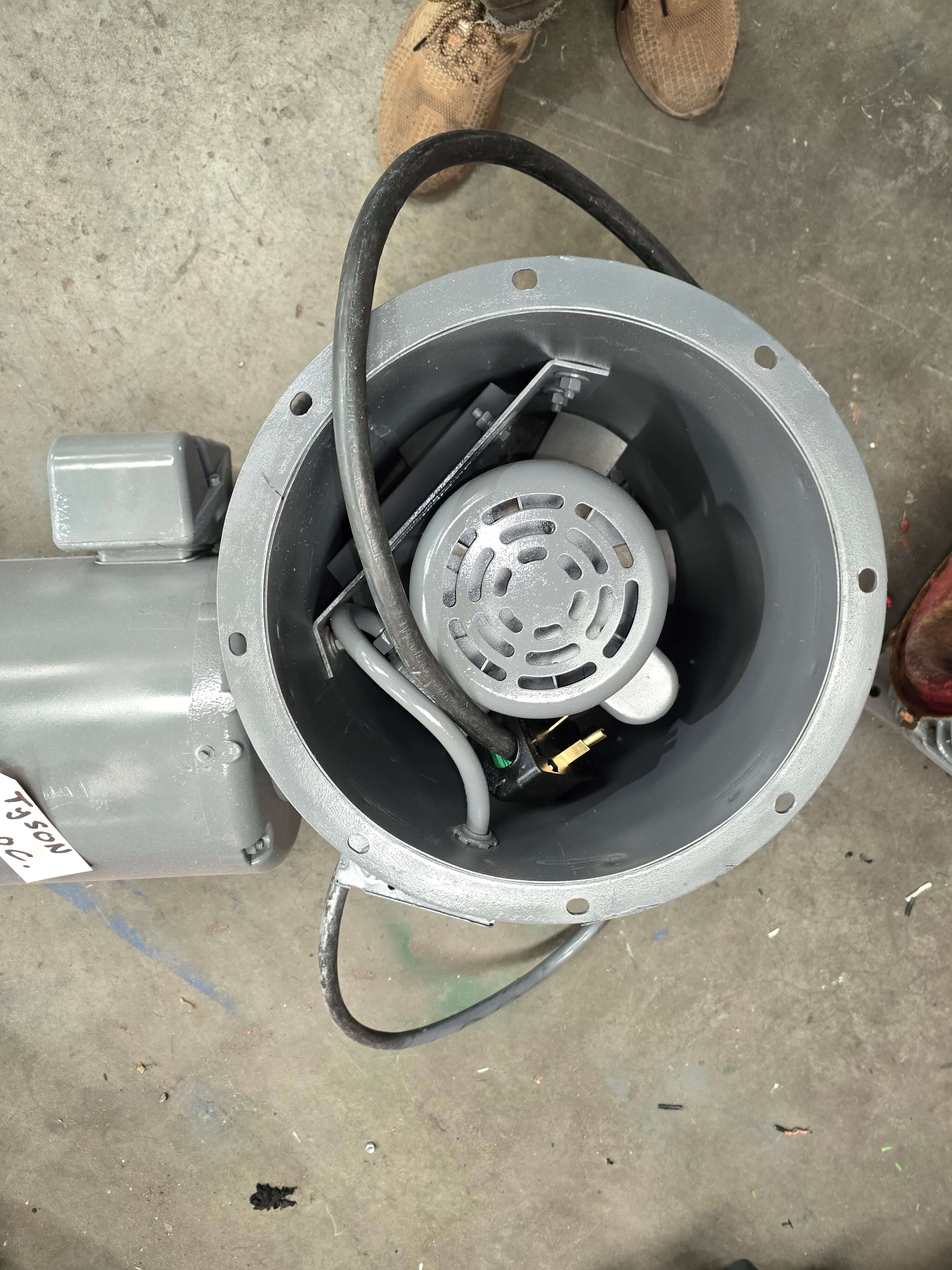

For 10 years, Industrial EQ Diagnostics has successfully repaired and rebuilt AC/DC motors. We staff certified technicians and machinists with state-of-the-art training and skills. Our focus is on quality repair, reliability, and turnaround. Think of IED whenever your company needs a motor evaluated, tested, or repaired.

So right now, the question could be, why electric motor testing is an essential service for your business? Following are four benefits of performing AC/DC motor testing for your business.

Regular testing of electric motors enables your company to determine whether a motor is malfunctioning before it actually fails. So how often should a motor be tested? Well, it depends on many factors including how critical the motor is to production, the process it is running, operating conditions, and many others, but a general rule of thumb is that a critical motor should be tested at the very least annually, as a catastrophic motor failure can lead to significant disruption of streamlined processes. This makes it possible for your business to develop a plan for continuing ahead of time.

By preventing motor failure by knowing the actual condition of a motor, businesses can eliminate the collateral damage and maintenance costs associated with motor failure. It can also lead to playing the waiting game with motor repairs or purchases, and no one wants to wait. In terms of repair or replacement, testing will help you decide the most sensible course of action — saving you money in the long run.

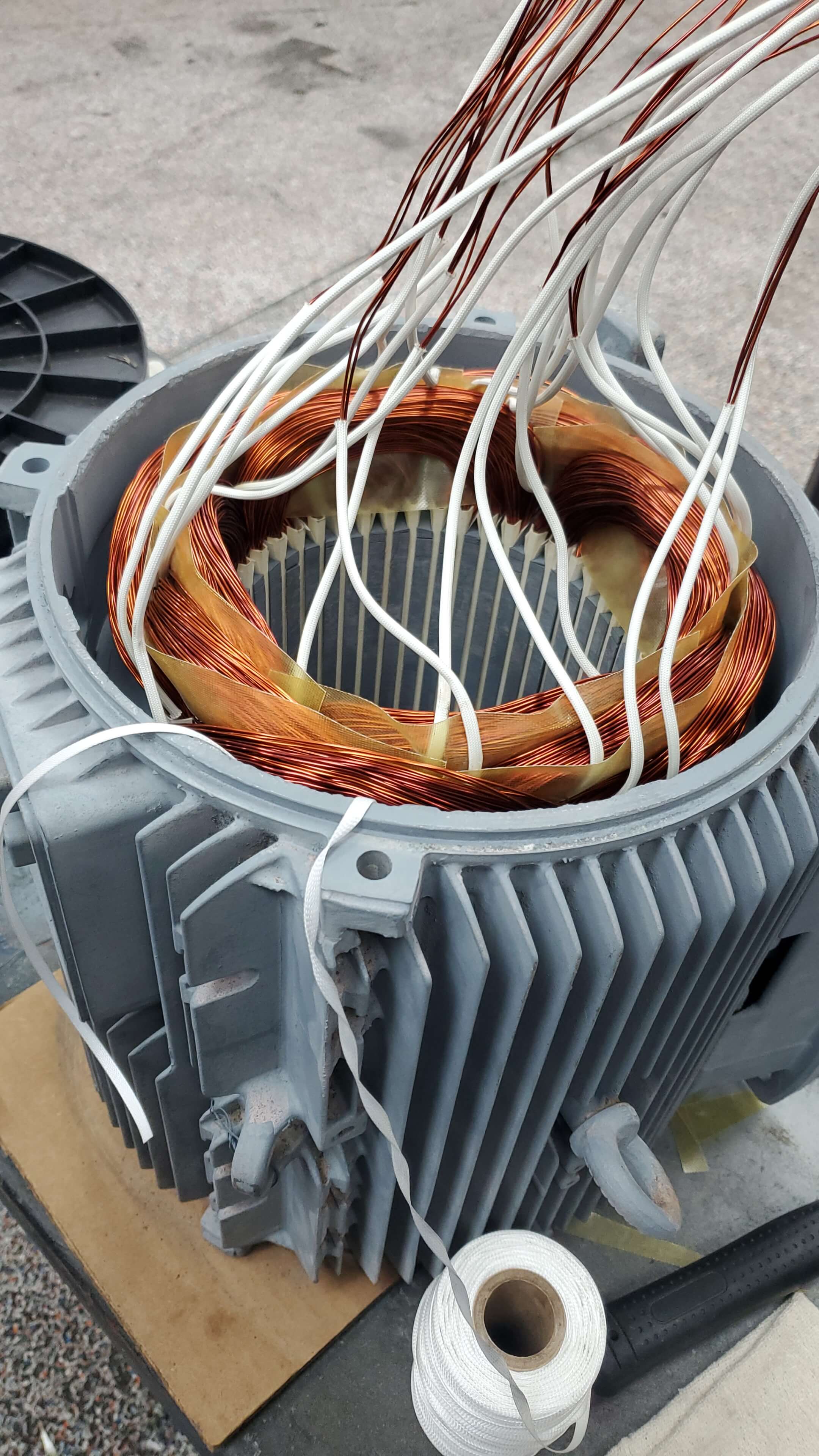

There are a variety of problems that can cause a motor to consume more power than it should. When these problems happen other components related to the motor might suffer premature and accelerated wear. Electric motor testing identifies issues with a power supply that might be cutting a motor’s life and bumping up energy bills. It can also show when a high-efficiency motor has been incorrectly rewound or suffers core loss and not performing to its ability.

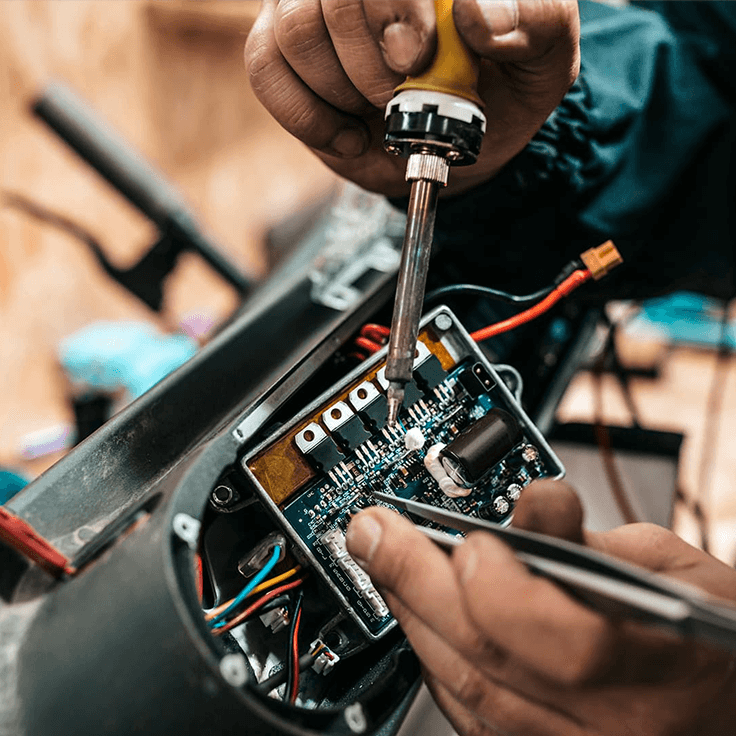

This can create unsafe conditions for users operating connected machinery. Motor testing identifies potential problems with electrical connections in a motor circuit that may not be detected by infrared inspections of the motor. This minimizes the chances of electrical fires.

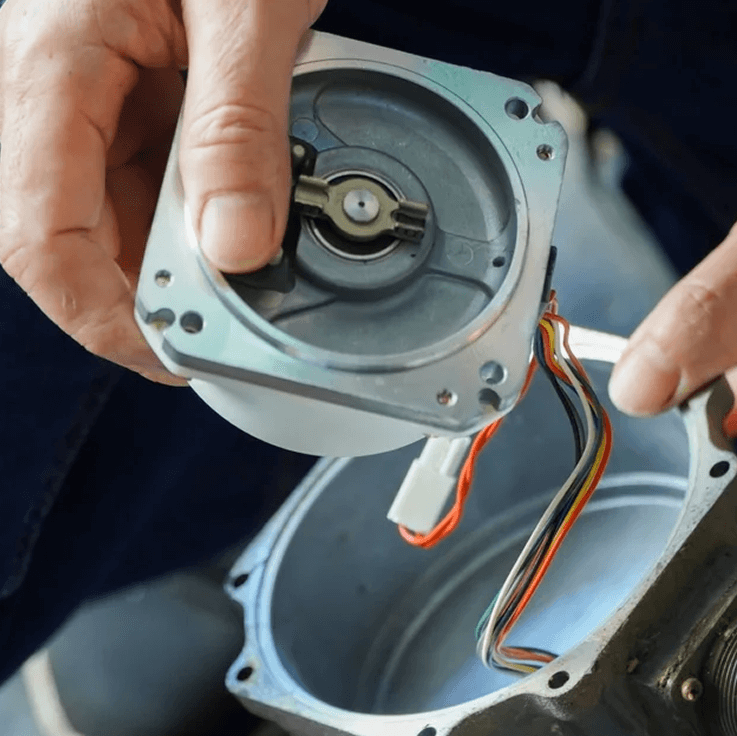

There are multiple forms of motor testing utilized to determine problems. The two main options are dynamic and static.

Dynamic, or online testing, takes place while the motor is in operation. From this, technicians can pull information on the quality of the motor’s power and its operating condition. Dynamic testing uses equipment to gather data such as:

This sort of motor test should be carried out regularly since it identifies issues with the unit’s components. Foreign object damage (FOD), rotors not properly stacked, and low torque from tapered fit also get revealed in the static testing process. As you can see at the top, this testing method occurs when the motor is off. Dynamic and static testing is advised to ensure a motor is running as designed.

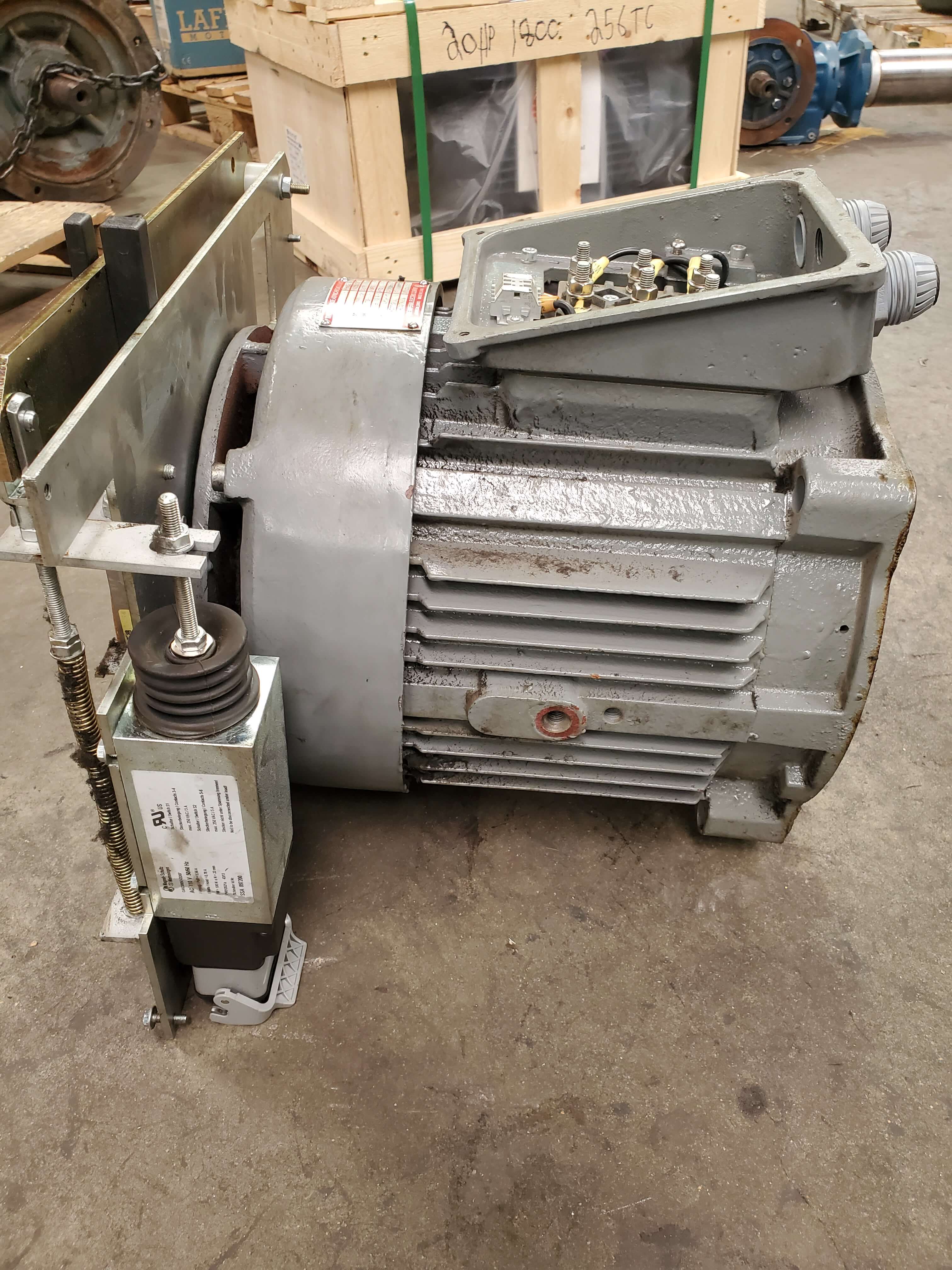

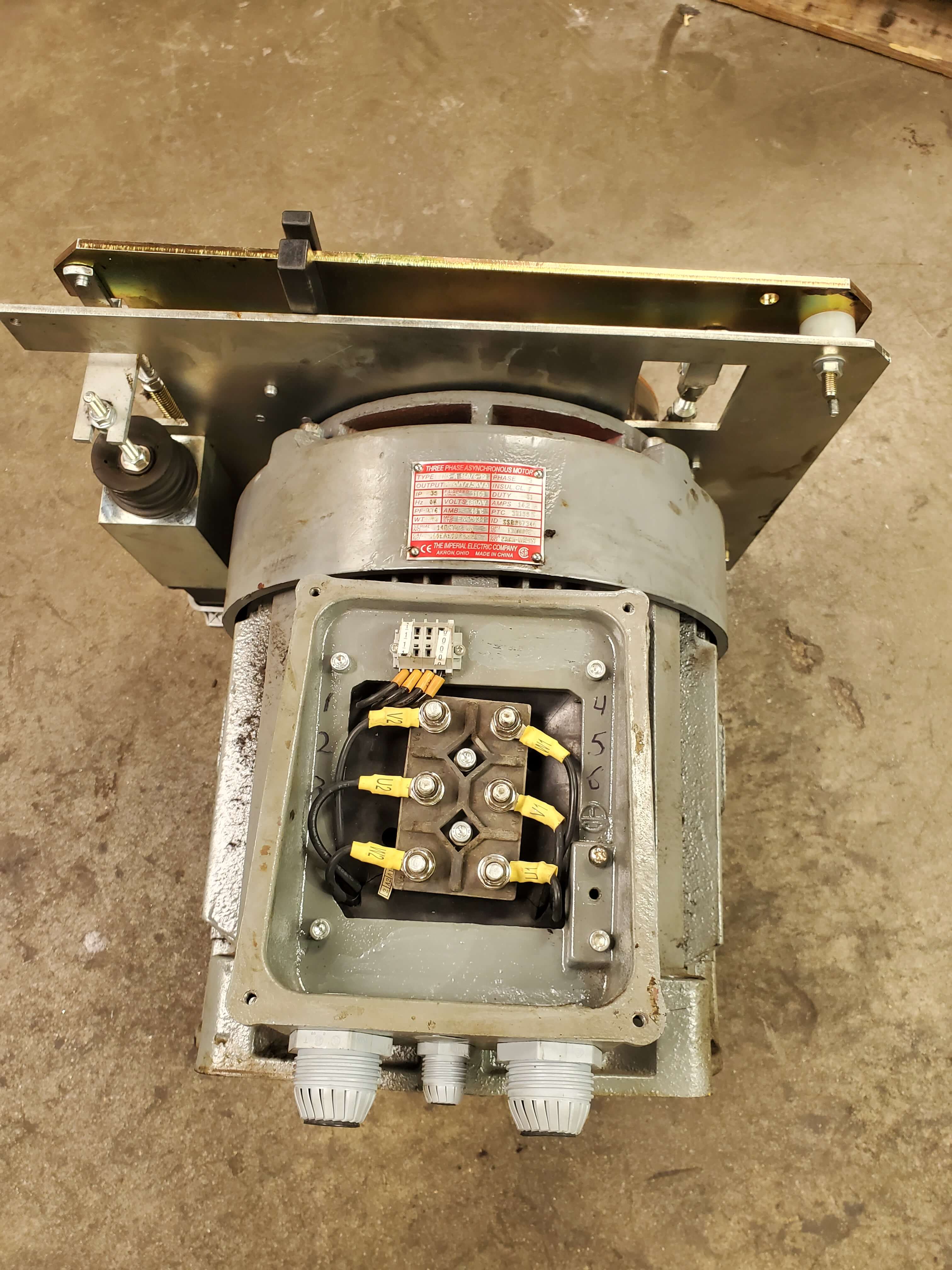

For industrial or commercial applications, the most common type of motor is a three-phase motor. The tests for a three-phase motor employ both static and dynamic test methods with a process typically covering the following tests:

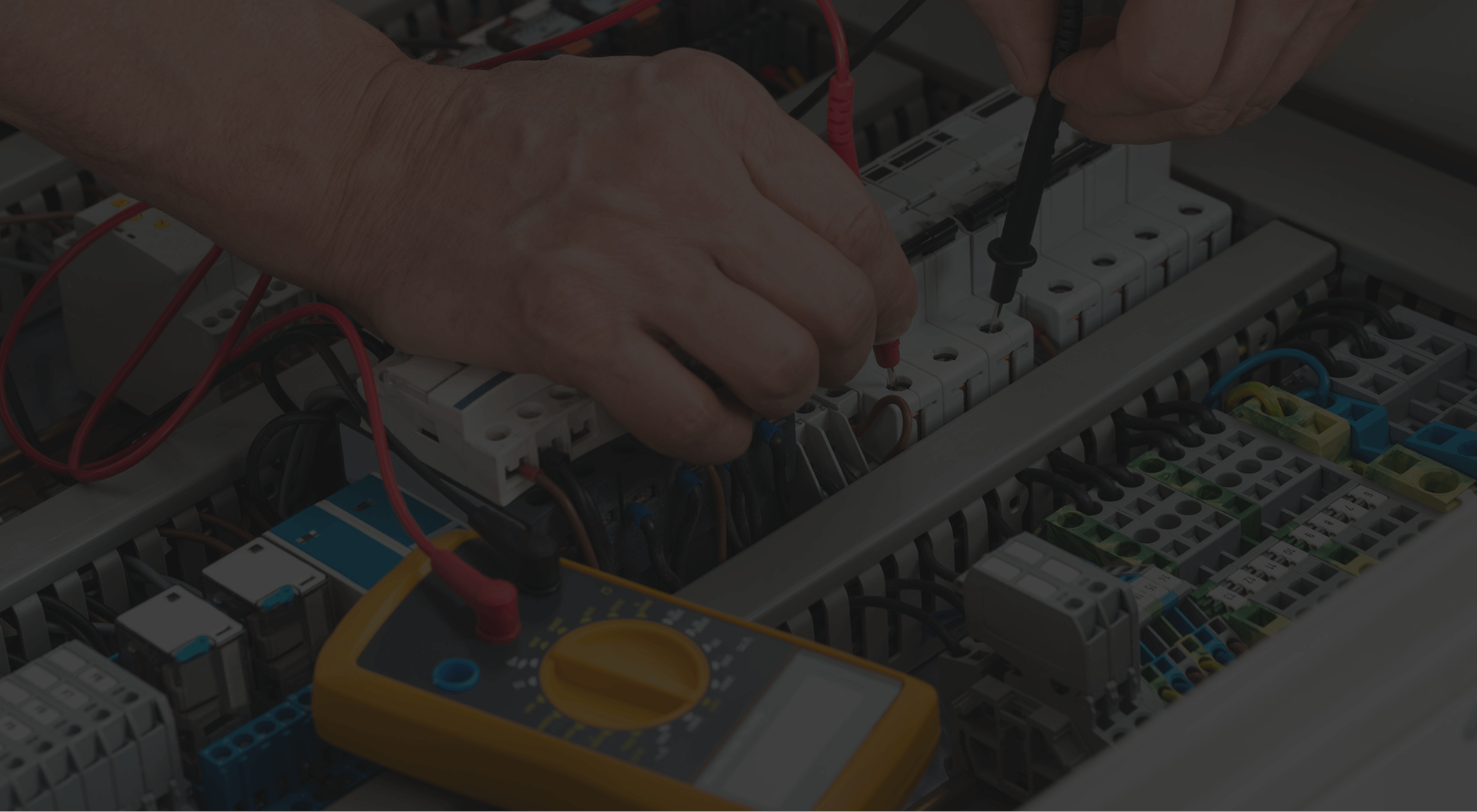

1. Earth continuity and resistance: This test is conducted with a multimeter and determines the resistance between the ground and the motor body.

2. Voltage supply: This check will tell you if the motor is getting the correct voltage.

3. AC motor winding continuity: Testing the continuity of winding at each phase will be a good indication of a burned-out motor.

4. AC motor winding resistance: This test checks if the ohm reading for each winding is the same or approximately the same.

5. Insulation resistance: In this type of motor, resistance can be measured between motor windings or phases as well as in every motor phase and motor frame.

6. Running amps: This test identifies discrepancies from the motor’s rated full-load amps.

Here’s the five-step process a motor follows when sent to your company for testing or repair to provide quality service:

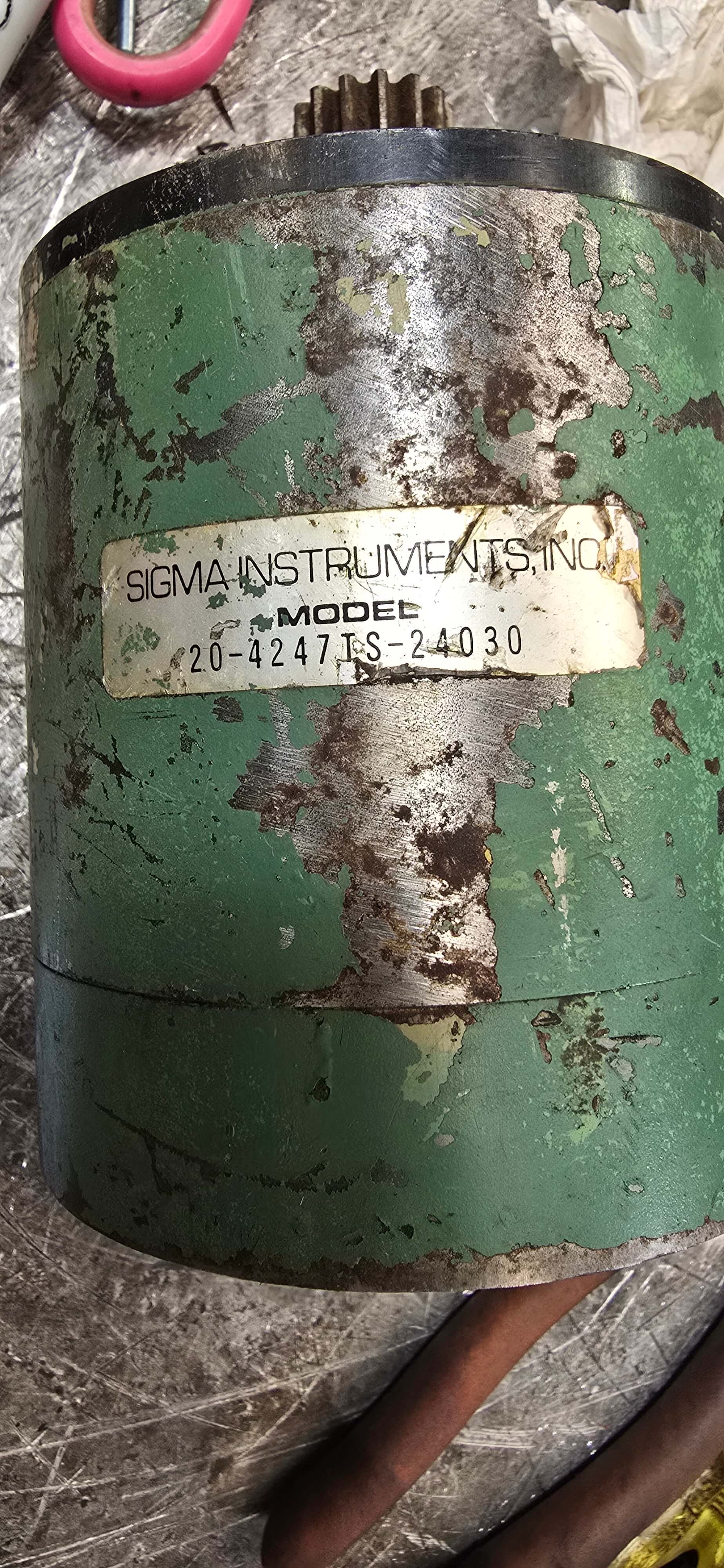

1. Initial receipt: Once we receive the motor, we enter the unit into our system and assign it a unique bar code so that you can track the progress through the process.

Electric motor problems such as the failure to start, intermittent running, hot running, or frequent tripping of the overcurrent device can originate from various causes. It might be the power supply or if there is a jam or binding or mismatch in the driven load or something. Otherwise, it can be a defect in connection like winding failure or burnt wire in the motor.

Just as with diagnosing any system, being able to test to find problems before they happen will require a full suite of electric motor testing gear that can acquire data from each part of the motor. Industrial EQ Diagnostics uses the following equipment to perform motor testing.

All testing services are performed using the highest quality, industry-leading equipment at Industrial EQ Diagnostics. Guaranteeing maximum accuracy and enabling us to compile all important data for each motor we test.

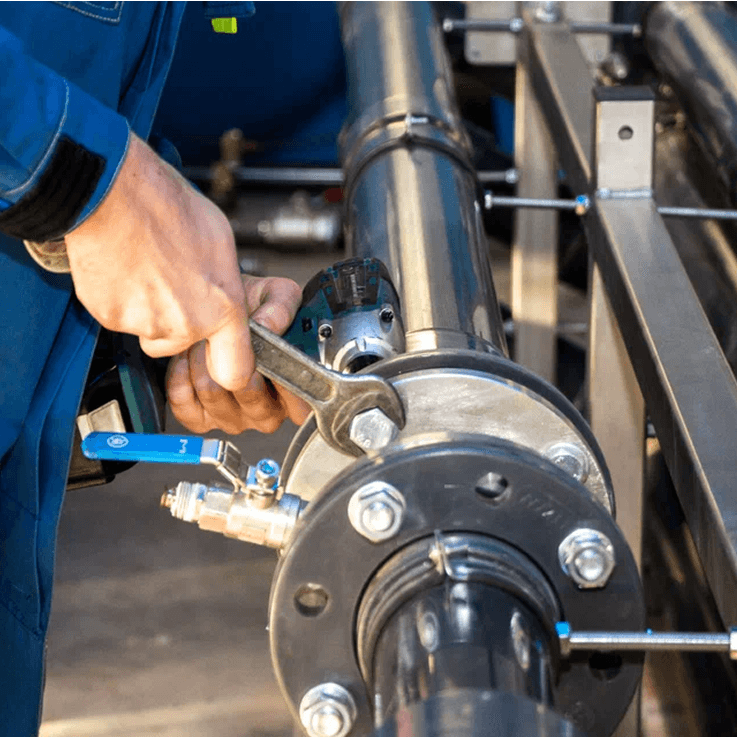

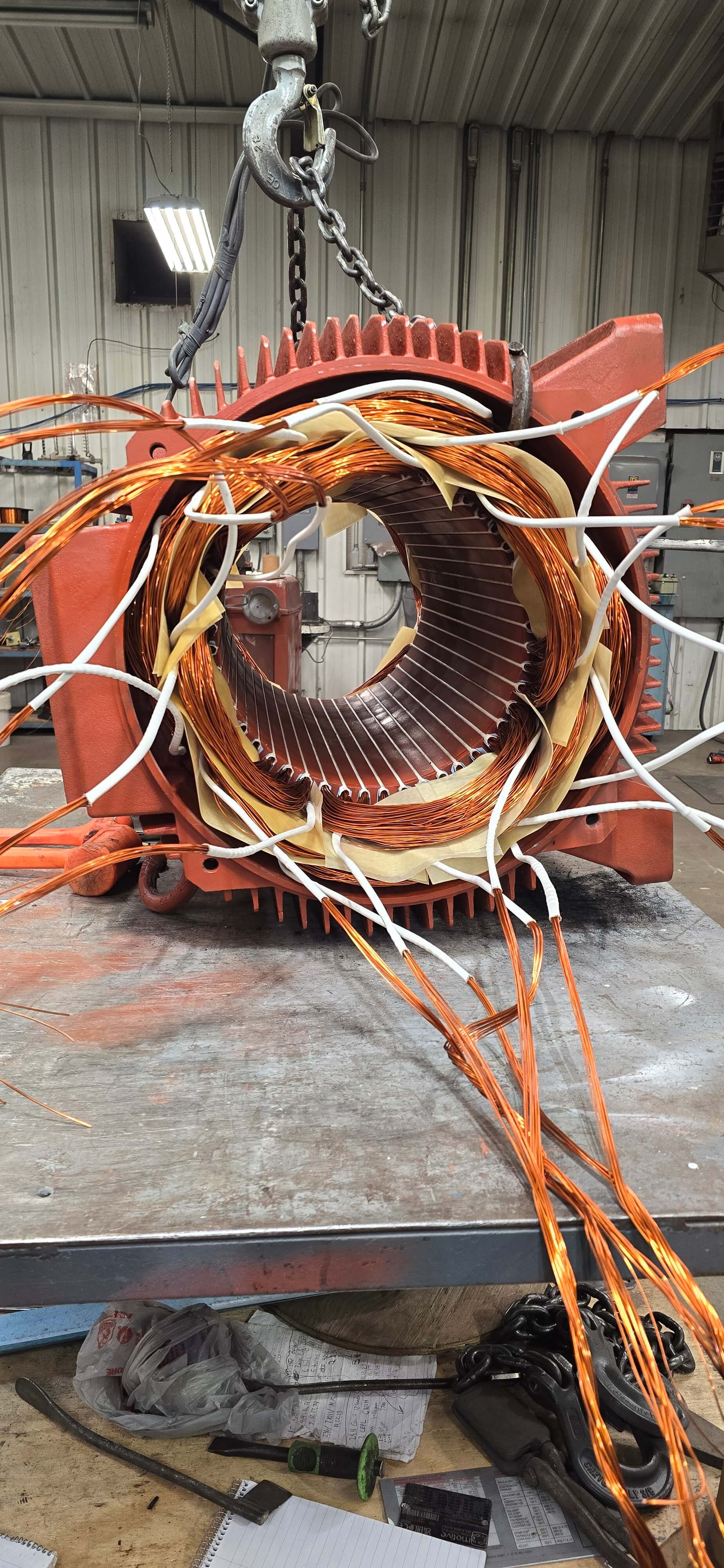

In addition to DYNO electric motor testing services, Industrial EQ Diagnostics performs a wide range of work and testing on your company’s AC/DC motors. We offer a full in-house rebuild and repair shop with machining capabilities to ensure you have a motor in perfect working order.

A complete testing plan also indicates your company’s motor is put to practical testing, so it’s proven to be durable and ready to be reinstated into your operations. All of our parts & services are covered by a 2-year in-service warranty.

On top of that offer, we’ll also beat any competitor’s price when you bring us a qualified bid. We’re so confident that we can repair or build your motor and get it back to you that we provide a standard repair time of one to five days and a free one to two-day rush service if needed.

Give your company the cost-savings and efficiency maintenance it needs, plus have a team of qualified customer service representatives available to you 24/7/365 to discuss the status of your repairs and to provide any additional information you may require. For even more convenience, you can get a quote online.