Nothing is more frustrating than a busted piston pump within your company’s hydraulic system. Don't waste time worrying about downtime and having to replace the whole unit, partner with Industrial EQ Diagnostics. To provide the best hydraulic repair service on pistons, our techs are always trained and ready to get you back in operation, at a faster pace.

Rather than jumping into our repair services blindly, we ensure to check what the scenario is so we can take the correct troubleshooting measures. Our factory-trained certified technicians provide sophisticated repair services to various industries.

Once we know the problems your hydraulic pistons are dealing with, we replace broken, damaged, or worn parts and repair failed components as needed. After our critical repairs and replacements, we run hydraulic tests so that the system operates at peak performance.

Although some faults can be trickier to find than others, our expert engineers have the very best technology at their disposal and they combine this with a wealth of experience to find many different types of piston pump issues. We deliver fast, effective, and efficient piston pump repair services which enable us to deliver top-quality solutions.

Confident hydraulic piston pump repairs by Industrial EQ Diagnostics keep your company operations feeling good. We identify problems with the hydraulic system and that enables quick turnaround time so that you can get back to moving.

We support every industry on the market — it doesn’t matter if you are in a manufacturing, laboratory, home, or office sector, our technicians have seen it all!

At Industrial EQ Diagnostics, our commitment to quality and service aids you in getting a broad scope of piston pump repair solutions:

We will never put you second and keep your business running every time. We are available 24/7/365 for your support as well.

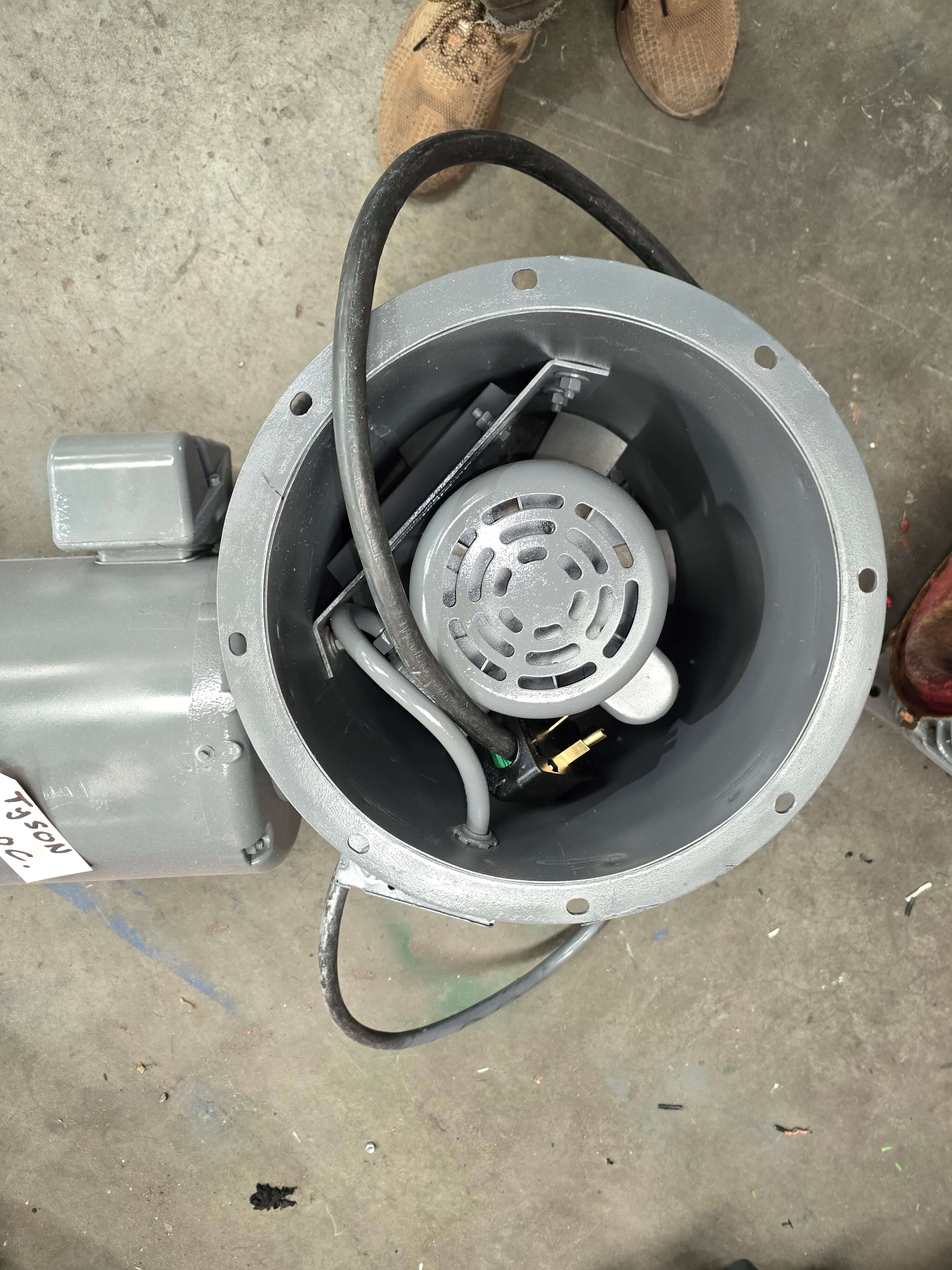

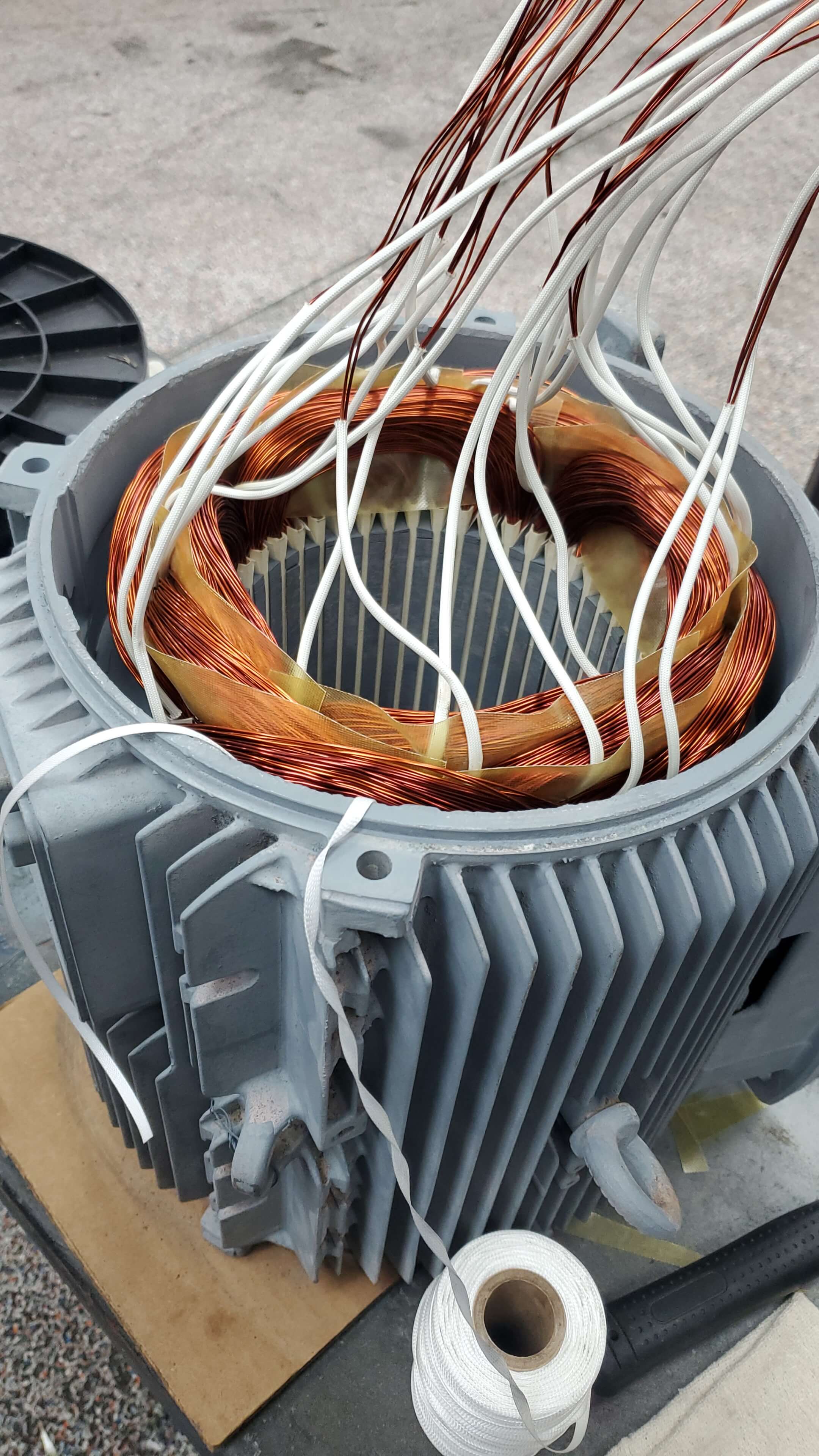

Disassembly is the starting step of repairing the pneumatic hydraulic piston pump. We disassemble the axial piston pump to inspect and measure it, noting down the dimensions of each component. After inspecting the entire unit and identifying the problems, we prepare & send a quote to give you an idea of what needs to be done.

If we receive the green light to proceed with our repairs, we begin by cleaning the unit. We lap the rotary parts and end cover, then ensure the fit of the bearing and shaft. The play of the pump is adjusted by our technicians and kept within tolerance.

We perform necessary repairs, replace critical parts, and reinstall the rotary components. Our specialists test the hydraulic piston pump after we finish the whole process. We then calibrate it, and if it’s working at a peak level, send it off to painting and finishing. And if it’s still not good enough, we go back to make corrections.

Repairing and replacing these essential hydraulic piston pump parts is a more economical solution than replacing the entire unit. Although the source of a pump’s failure can come from a multitude of sources, many fall into a few areas, such as:

In many cases, trouble is a result of wear and tear. Excessive heat, cavitation, extreme pressure, and contamination can cause premature failure of your piston pump too. Another reason for failure is incorrect installation — all of which we can fix on the spot.We employ advanced software, digital controls, and integrated electronics to refurbish your company’s piston pumps. Industrial EQ Diagnostics deals with the growing complexity of hydraulic systems. Our licensed technicians inspect, repair, test, and calibrate an array of piston pump problems.

Industrial EQ Diagnostics provides hydraulic and pneumatic maintenance service and repair. With better solutions at a better price, resulting in valuable and reliable repairs.Get your free online quote anytime, or contact us at 111-222-333 to learn how we can help your business. Our specialists can address anything concerning your hydraulic piston pump unit to keep your downtime to a minimum.

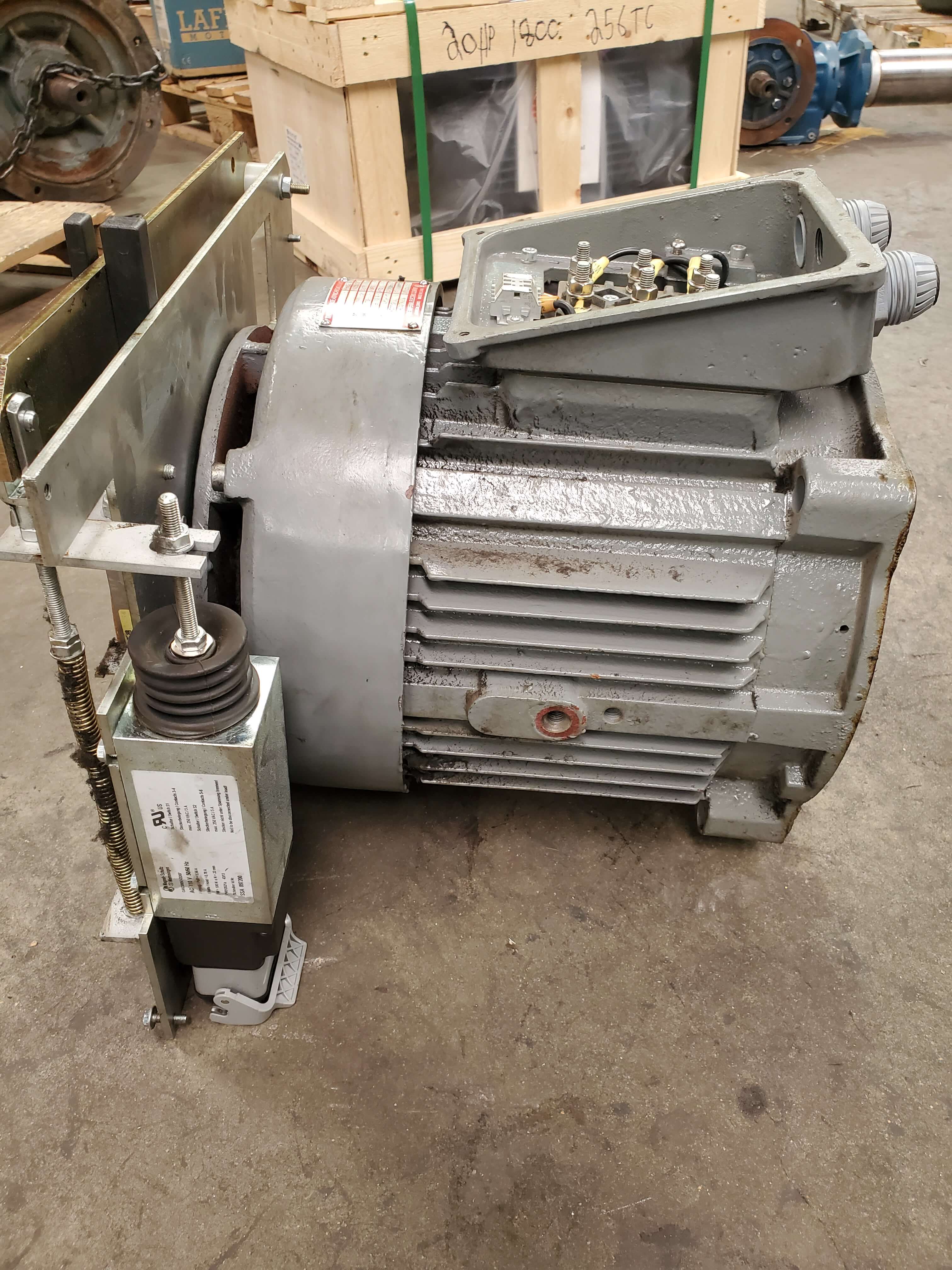

Hydraulic motors are used in applications where the power source is a hydraulic system, and it is impractical or uneconomical to have electrical power. These motors are useful in that they can get exceptionally heavy loads for a given motor frame. Hydraulic repair services consist of going to lengthy engines needing lots of expertise. Hydraulically operated devices await solutions and your business requires repair, so reach out to specialists who understand these motors and effective means to prolong their life.