When companies and manufacturers send us their hydraulic motors for repairs, we follow a sweeping process with the devices to ensure that we perform any and all necessary repairs and restorations for them. Repairing involves more than fixing a single broken part. Instead, we aim to refresh and renew the entire hydraulic motor to help revitalize its life and efficiency. Here are the following steps in our process:

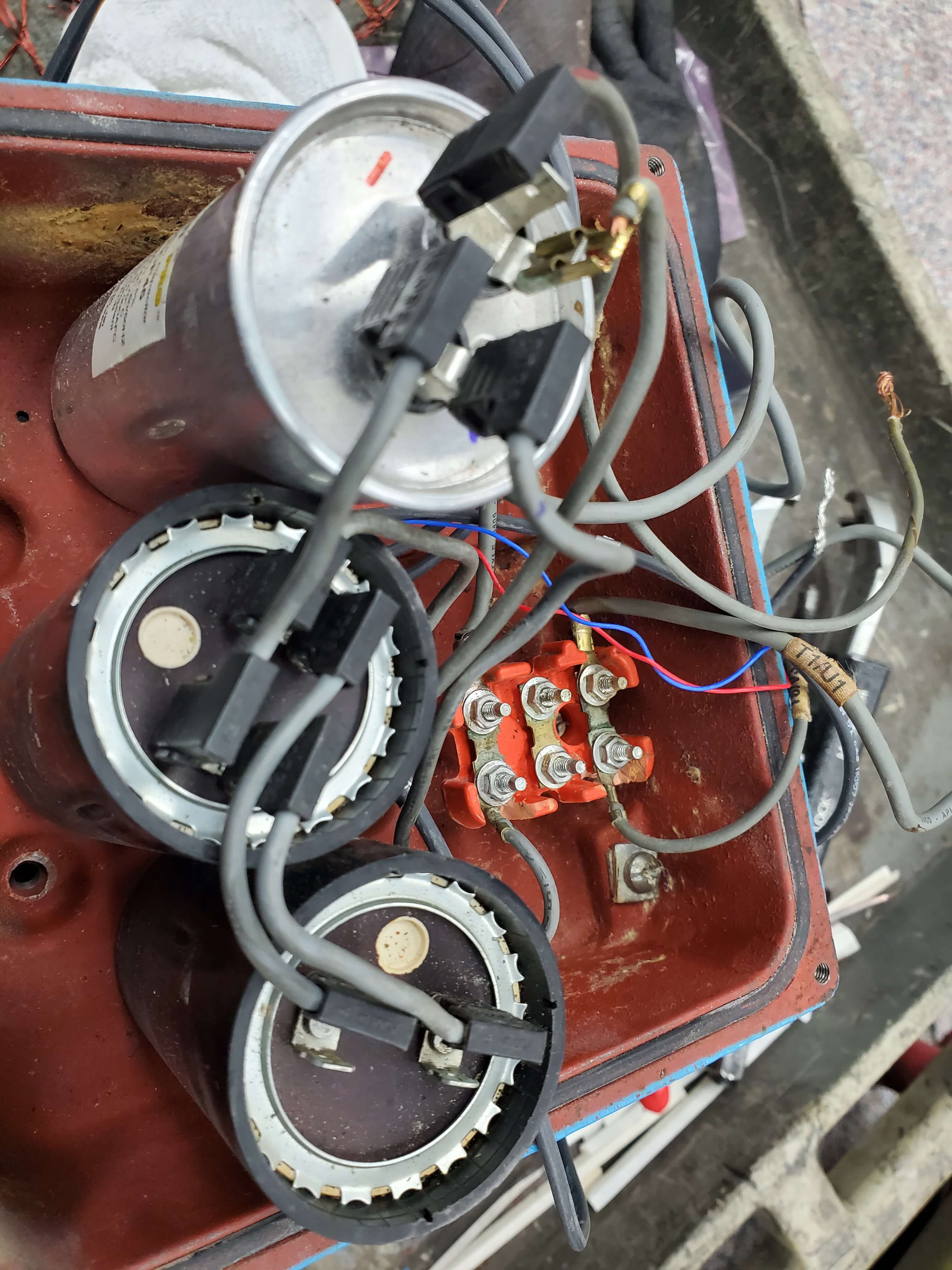

First, we disassemble the engine to get at all the bits. Everything gets a thorough inspection and we control the disassembly process to avoid the parts getting damaged. Removing and inspecting the motor’s components helps our technicians decide what parts need cleaning and restoration.

Here are some of the components we analyze, and may repair or replace:

The next step is to clean and inspect the parts. Removing oil buildup has the advantage of allowing us to examine the condition of the motor parts more closely as fluid or oil is continuously flowing over parts for hydraulic motors. The inside of a hydraulic motor can be contaminated by hydraulic oil, fluid, or cleaning agents. Cleaning this debris can lessen the friction and enhance the motor's working.

Electronics that regulate the motor operation require inspection and testing. With this step, the technician can better find the source of motor issues. In some cases, the motor may only require repairs of the electronics to restore operation.

Repeated pounding of pistons and shafts can over time cause scouring of the surface. Our technicians have multiple ways of eliminating the scoring. Minor pitting and scoring can be removed with occasional honing or polishing. We can also re-chrome the surface for more serious cases.

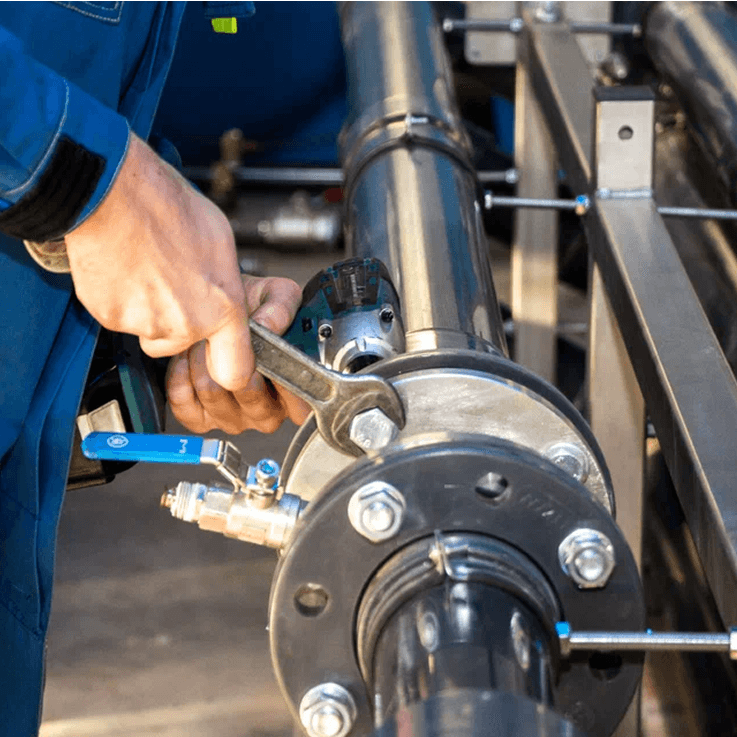

If something is stuck inside the cylinders or anywhere else where a shaft or piston must be, we do just exactly as we do in restoring pistons and shafts. Damaged cylinders may require machining; broken shafts may be replaced in those cylinders. Finally, for gear motors, we check tooth integrity and change out any worn or broken gears to keep things runny and smooth.

New seals, bearings, and gaskets will be installed to replace any that show signs of wear. Components like these, when worn out, can lead to leaky fluids and inefficient operation of the motor as a whole.

Since hydraulic motors are highly dependent on pressure and flow, we have to make sure that fittings meet tolerances and allow the system to build and hold the necessary pressure. Tests we perform include a pressure test and specification test at 1,000 psi pressure and 150 gpm flow.

Once all the restored parts are replaced, the unit is tested at a known rpm, ensuring it meets proper torque and pressure requirements.

We're your one-stop shop for hydraulic and pneumatic maintenance service and repair. There’s no one else you need. We’re going to do it right and do it fast and do it at a price that you can afford.

A busted hydraulic motor shouldn't cost your business production time. Resolving it through our standard repair service takes one to five days; a rush service gets you back on track in one to two days. Contact Industrial EQ Diagnostics or request a quote if your company requires a reliable hydraulic motor repair shop.