AC and DC drives are essential parts of numerous industrial machinery. If one of them goes down you risk a tremendous loss in productivity and revenue, since it powers the core of your hardware. Depending on the role you have within your team it can be difficult to know whether or not your electrical AC and DC drives are operating at their most efficient, but you need to make sure you have the right one for the job and that you take care of it accordingly.

Electrical AC and DC drives have advantages and disadvantages, also suitable for selective environments. Let’s quickly discuss how AC and DC drives function and what you should look for in an AC and DC drive repair service.

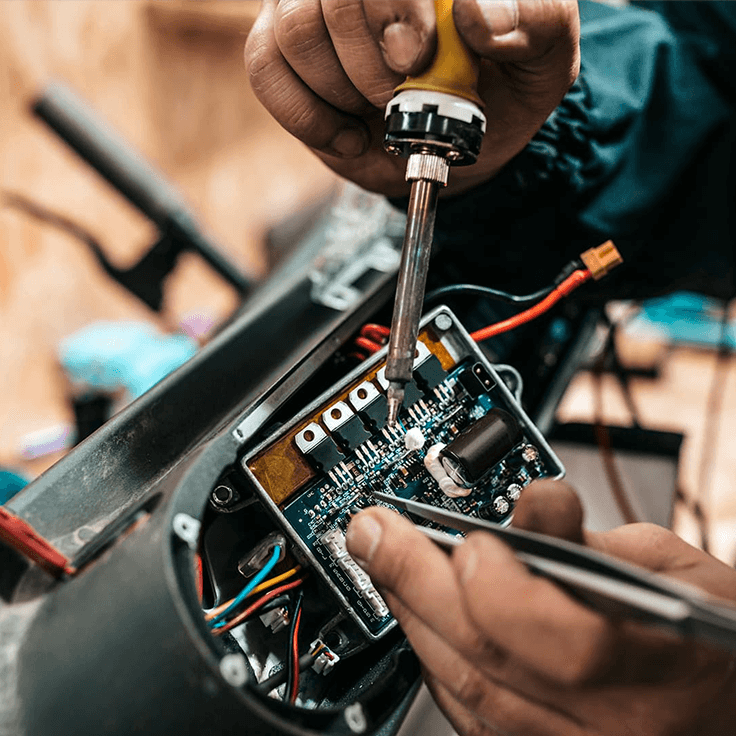

AC and DC drives are two different types of technologies used to control the speed of an electric motor. AC drives are much more popular and are used in most applications, however, DC drives are implemented in some situations. Both are used to blow electric energy into the motor at various speeds for mechanical power. You will see them acting as the muscle behind machines like conveyor belts, pumps, cranes, and ventilators around industrial environments.

AC and DC drives are essential parts of numerous industrial machinery. If one of them goes down you risk a tremendous loss in productivity and revenue, since it powers the core of your hardware. Depending on the role you have within your team it can be difficult to know whether or not your electrical AC and DC drives are operating at their most efficient, but you need to make sure you have the right one for the job and that you take care of it accordingly.

Unlike AC drives, DC drives use the same basic principle, but instead convert the AC current to DC to power a DC motor. It does not go back to other original ACs, and thus its circuit is similar to those of an AC drive, but with the rectifier and output in one stage. Most DC drives use a method called a thyristor bridge, often with similar SCRs to the ones in an AC drive.

DC motors have speeds that are directly proportional to the voltage that you apply to the drive’s armature. This makes the DC motors a “no-load” type. If they are given a torque load that increases gradually at a fixed voltage, they will slow down. The controls of the DC drive compensate for this change. The motor torque is independent and is generally throttled by the current supplied to the armature.

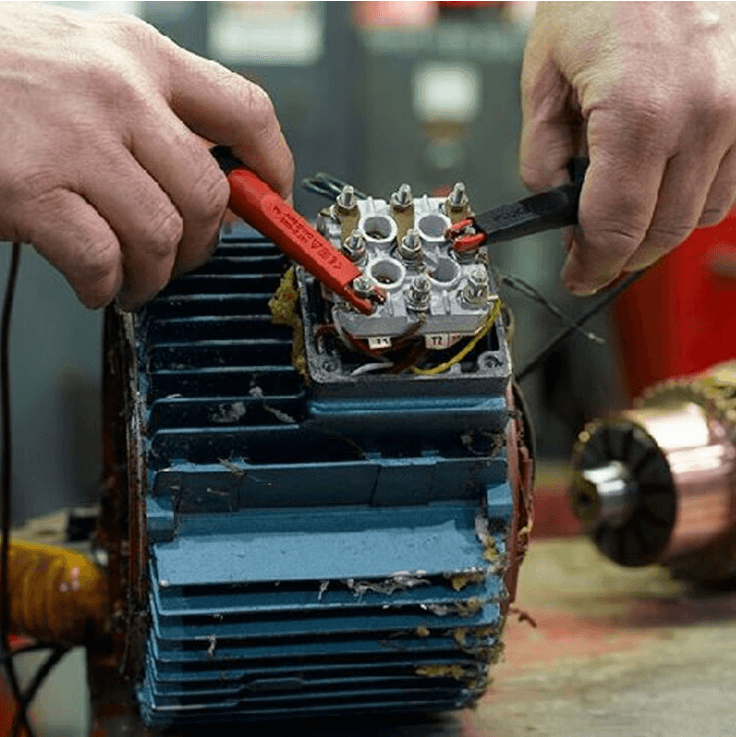

Because of their different designs, however, these drives are usually more suited to certain tasks. DC motors are best for certain specific kinds of machine uses (like high-unit torque needs), while AC drives are used more where the motor operates at a fixed speed.

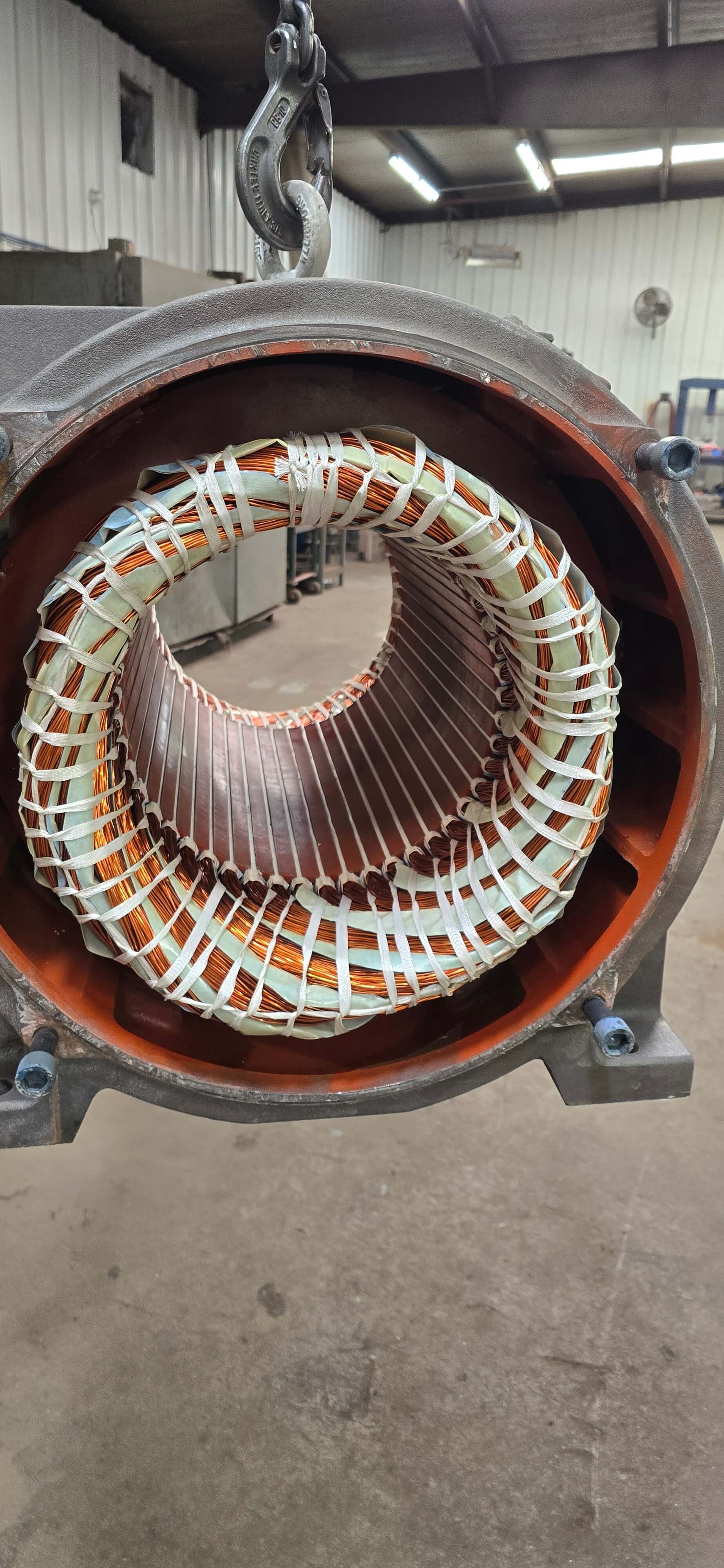

One of the most widely used applications of AC drives is heating, ventilation, and air conditioning (HVAC) applications, which are prevalent with anything from fans to compressors to pumps. If a fan or pump is driven by an AC drive rather than by other means such as valves or dampers, the system can conserve energy by providing only what is really needed, rather than supplying additional energy and then reducing it afterward. Not only does this save energy and reduce stress on the components but it can also bring down the noise levels.

Even though AC drives are now getting close to the benefits of DC drives, DC is still the preferred drive for heavy-duty applications like cranes, hoists, crushers, elevators, and many others. It is safe, cost-effective, and gives you the outputs you need to use those powerful pieces of equipment.

Trust Industrial EQ Diagnostics to deliver fast, reliable, and high-quality industrial repair solutions whenever you need them most.

Regardless of whether your machinery runs on direct current (DC) or alternating current (AC) drives, you will most likely have to service or repair them at some point. When that time comes, you want a partner that is trusted and reliable to assist you in conducting the service. Well, here at Industrial EQ Diagnostics Inc., our team of AC and DC drive repair experts can provide you with just that. They’re intimately familiar with these electrical drives and are able to diagnose and fix countless issues in order to have you back up and running in no time.

We’ve been helping users of AC and DC drives keep things moving for years, in a wide variety of applications. By working with us, you will receive:

Our talented team is familiar with the drives of all the big manufacturers and we can provide AC and DC drive repair for any company. We also provide complimentary assessments, and you won’t be charged unless we discover an issue.

Click here to find out more about how Industrial EQ Diagnostics can help repair an AC or DC drive or request a quote today and let us get your machinery back in action.